rockwell hardness file test|rockwell hardness tester diagram : manufacturers An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set allows you to quickly ascertain the hardness of your material. Watch resident tech expert Kurt Repsher . web14 de nov. de 2017 · Subscribe: https://www.youtube.com/user/teamevga?sub_confirmation=1Sonic is fast, but so is the EVGA GeForce GTX 1080 Ti FTW3! Check out .

{plog:ftitle_list}

WEB12 de dez. de 2022 · Best Close Quarters Loadout. Weapon 1. Fennec SMG. Weapon 2. Signal Sniper Rifle. One of the most difficult aspects of Warzone is clearing buildings and other close-quarter areas. The Fennec .

An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set allows you to quickly ascertain the hardness of your material. Watch resident tech expert Kurt Repsher .Rockwell Hardness Testing File Sets. Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C- scale. .

Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration . A Rockwell hardness tester. The Rockwell scale is a hardness scale .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .

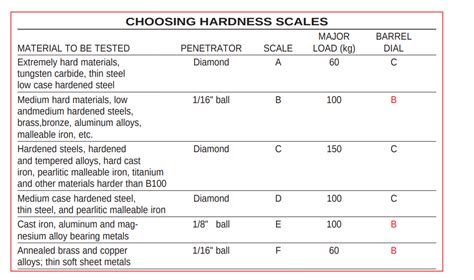

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: . How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..

The testing of a blade with a file only happens after the quench where the blade is at maximum hardness. It is just a test to see if any hardening occurred, not to test the final hardness of the blade. After tempering, a file will cut a blade relatively easily. Matthew Parkinson makes hardness testing chisels in the lower rockwell levels for .

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. . File Testing. This is the classic, easy way that .Test your knife hardness on the Rockwell C scale with this testing file set. Files from 40 RC to 65 RC are included in a custom-fitted case, along with complete instructions and a conversion chart for Rockwell to Vickers. . These high-quality hardness testing files feature specially curved tips for testing internal slots and grooves as well .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was created to determine the hardness and strength of materials. After executing the Rockwell hardness test, you will be able .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Rockwell Hardness Testing File Sets . Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file.Machine Shop SolutionsProblem: Hardness testing can require time-consuming tabletop hardness machines, barrel dial or indicator setups. Solution: The scratch test set can be used on workpiece, quickly and easily, without set-up!Skip The Setup For Fast & Easy Hardness ResultsBring convenience and portable testing to your shop with the TTC Hardness Tester .A unique set of 6 specially shaped files, each w a non-slip grip, color-coded handle. The Rockwell value is printed on each handle and the files range from HRc 40 through HRc 65. Precision testing files have specially curved tips which can reach into internal slots, grooves and bores. hardness testing files

• Each file has a non-slip grip colour coded handle for hardness assessment, with the Rockwell value printed on each • Files range from HRC 40 through HRC 65 • Set comes complete with instructions and conversion chart Rockwell C .

Ordinary versus superficial In reality, there are two separate kinds of Rockwell test procedures. The Regular method and the Superficial method are these. The Regular technique is often referred to as the Rockwell method (AKA Super . The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of .

Bring convenience and portable testing to your shop with the TTC Hardness Tester Set, complete with 6 color-coded files ranging from 40 to 65 in Rockwell hardness. Complete your tests anywhere, and avoid the time-consuming barrel dials and indicators setups tabletop hardness machines require.This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file. Using these hardness files to test hardness of annealed and heat-treated tool steels in my shop. Measures Rockwell C-scale hardness within a few points, not a precise testing tool but is not intended or advertised to test more precisely than plus or minus a few points of hardness. Certainly adequate for my purposes in tool making and woodworking.High quality Japanese made Hardness Test Files are an easy to use, quick and inexpensive tool used to approximate material hardness in Rockwell scale. Usage is simple. Just slide the test files across the surface, one by one, starting from the hardest until reaching a file soft enough to not record a result. Based on reaching a non-result, the .

Rockwell Hardness Testing File Sets . Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file.Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .These files are generally unsuitable for anything that would require a particular hardness, like a knife, blade, or hard tooling. . you can sharpen and test the edge. Or just do a file test (file testing a file? . (aside from a super expensive Rockwell tester of course) is to use hardness testing files. It’s basically a set of different .

Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta-geous for applications where it is not feasible to transport samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1 3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3.1.7.4 movable Rockwell hardness testing machine a Rockwell hardness testing machine .

typical rockwell hardness of materials

rockwell hardness tester diagram

WEB7 de fev. de 2024 · Sobre a UTFPR; Estrutura; Documentos; Editais; Comunicação; Comissões; Avaliação Institucional; . Calendário acadêmico e Horário de disciplinas / Calendário 2024-1- Atualizado. Calendário 2024-1- Atualizado Calendário Acadêmico 2024-1_atualizado_07-02-24 .pdf. Reportar erro. Envolva-se; Comunidade; Contato; .

rockwell hardness file test|rockwell hardness tester diagram